Cold heading sleeve Manufacturer

Litšobotsi tsa mokhoa o batang oa ho etsa lihlooho

1. Sehlooho se batang se etsoa mocheso oa kamore.Sehlooho se batang se ka ntlafatsa thepa ea mochini ea likarolo tsa tšepe.

2. Cold heading forging process e ka eketsa phaello ea thepa.Ke mokhoa oa ho etsa khatello o thehiloeng holim'a deformation ea polasetiki, e ka khonang ho fokotsa ho itšeha kapa ho se itšehe.Sekhahla sa tšebeliso ea thepa ka kakaretso se ho 85% ka holimo, se phahameng ka ho fetisisa se ka fihla ho 99% ka holimo.

3. E ka ntlafatsa katleho ea tlhahiso.Nako le ts'ebetso ea lihlahisoa tsa tšepe li batla li le khuts'oane, haholo-holo likarolong tse ngata tsa ho etsa mechine ea ho etsa mechine, li ka ntlafatsa haholo tlhahiso.

4. Theknoloji ea ho forging e batang e ka ntlafatsa bokaholimo ba lihlahisoa le ho netefatsa ho nepahala ha lihlahisoa.

Litlhoko tsa ho bata hlooho forging tshebetso ka thepa e tala

1. Sebopeho sa lik'hemik'hale le thepa ea mechine ea lihlahisoa tse tala li lokela ho finyella litekanyetso tse nepahetseng.

2. Lisebelisoa tse tala li tlameha ho ba spheroidized annealing treatment, metallographic structure of the material is spherical pearlite level 4-6.

3. Ho thatafala ha lihlahisoa tse tala, e le ho fokotsa mokhoa oa ho senya thepa ka hohle kamoo ho ka khonehang le ho ntlafatsa bophelo ba tšebeletso ea hlobo, lisebelisoa tse entsoeng ka serame li hlokeha ho ba le boima bo tlaase kamoo ho ka khonehang ho ntlafatsa polasetiki.Ho thatafala ha thepa e tala hangata ho hlokahala hore e be ho HB110~170 (HRB62-88).

4. Ho nepahala ha thepa ea ho taka e batang ho lokela ho khethoa ho ea ka litlhoko tse khethehileng tsa sehlahisoa le ts'ebetso.Ka kakaretso, ho nepahala ha

5. Boleng ba holim'a lintho tse batang tsa ho taka bo hloka hore filimi e tlotsang e be lefifi le lerootho, 'me bokaholimo bo se ke ba e-ba le mengoapo, mameno, mapetsong, moriri, mafome, letlalo la oxide le likoti tsa likoti le liphoso tse ling.

6. Botenya bohle ba lera la decarburization ka tataiso ea radius ea lisebelisoa tse batang ha ea lokela ho feta 1-1.5% ea bophara ba thepa e tala (maemo a khethehileng a itšetlehile ka litlhoko tsa moetsi e mong le e mong).

7. E le ho etsa bonnete ba hore boleng ba ho itšeha ba ho theha serame, lisebelisoa tsa ho taka tse batang li hlokeha ho ba le sebaka se thata le boemo bo bonolo ba motheo.8. Teko ea ho forging e batang e lokela ho etsoa bakeng sa lisebelisoa tse huloang ke serame, 'me kutloelo-bohloko ea lisebelisoa ho thatafatsa ho sebetsa ka mokhoa o batang e lokela ho ba tlase ka hohle kamoo ho ka khonehang, e le ho fokotsa keketseho ea khanyetso ea deformation ka lebaka la ho thatafala ha serame nakong. deformation.

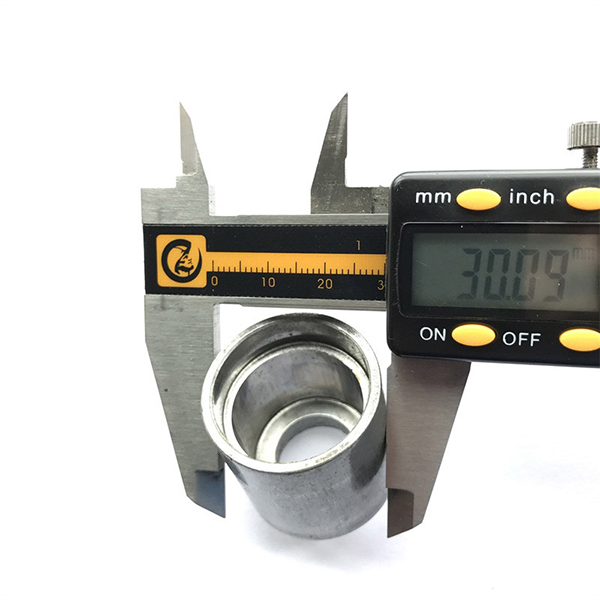

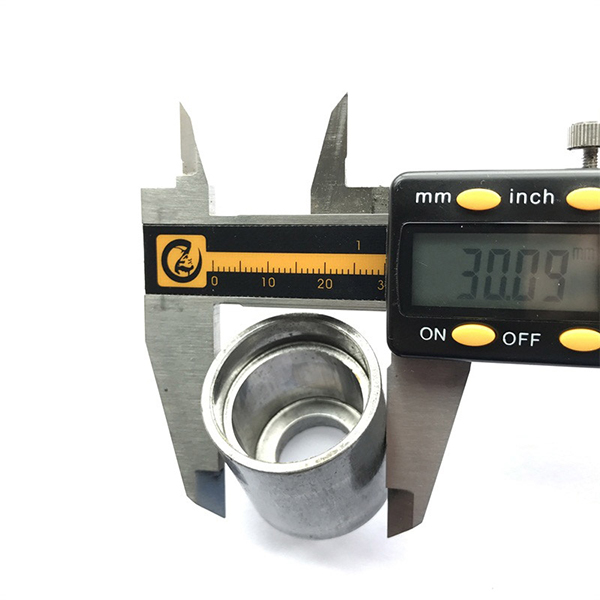

Pontšo ea Sehlahisoa